SPECIALIZED LINGERIE MANUFACTURER

Menu

Make Your Brand Stand Out with Custom Lingerie

Diverse Lingerie Products – Designed to Meet Every Need

Simply Complete Your Own Design

What type of customization do you need? Printing, logos, embroidery, or packaging? As a factory specializing in custom lingerie, we can accommodate all your requests.

Different printing techniques, logos, materials, and colors can create diverse effects, attracting various customers. With over 20 years of experience customizing styles for different countries, we provide expert advice to ensure you get the best products.

We simplify the process for you—just share your technical packages or preferred images, and we’ll handle the rest.

If you want to design your own branded lingerie, Starwin is your best choice.

Complete Lingerie Solutions Boost Your Brand's Edge

With 19+ year experiences of cooperation with leading fashion brands, Starwin provides custiomers with more efficient one-stop services and solutions. Build your brand with us. Receive free customized consultation Now.

All Categories

We can provide you with a full range of customized lingerie services.

Yarn Solutions

For samples, we offer 3+ yarn options based on your design and budget to ensure your satisfaction.

Low MOQ

Flexible order quantities to meet your diverse needs.

Accessories

We can provide customized small-batch accessories for you, such as hooks and eyes, straps, elastic bands and more.

Production Visualization

We ensure 100% quality inspection and keep you updated on production progress.

Logistics Solutions

Our reliable freight forwarder offers cost-effective logistics, lowering your customs duties and shipping costs.

AN IDEAL LINGERIE COMPANY HELPS YOU ACHIEVE YOUR GOALS

We specialize in lingerie manufacturing and can customize products to your specific requirements, including size, design, and material. Our goal is to deliver high-quality, tailored lingerie that meets your expectations.

Design Creation

This is the initial stage where designers bring creative concepts to life. It involves brainstorming, sketching, and creating design ideas based on the latest trends, client requirements, and brand aesthetics.

Sample Making

Once all details are confirmed, the fabric is cut according to the pattern. This step involves precision to ensure that all pieces match the design and fit specifications.efficiency and consistency in quality.

Fit Testing

Once the pattern is finalized, a sample garment is produced. This prototype allows the design team and clients to see how the final product will look and feel, giving an opportunity to assess any needed changes.

Fabric Cutting

The sample garment is tested for fit on a live model or mannequin. The goal is to ensure that the garment fits comfortably, moves properly, and achieves the desired look.

Bulk Production

After approvals, the garment enters full-scale production. Here, the design is mass-produced, with all quality and design specifications maintained to meet the order quantity.

Quality Inspection

Quality control is conducted throughout the production process. Each garment is carefully inspected to ensure it meets the highest standards for stitching, fit, and finishing.

OUR STORY

Starwin | Women’s Lingerie Since 2005

When our founder first touched the warp and weft of lace at his mother’s sewing machine, a philosophy of feminine empowerment was born, and in 2005, we transformed what began as a two-generation reverence for craftsmanship into a modern lingerie manufacturing system – Starwin is not just a name in the supply chain, but a design and development center that extends the reach of the brand’s customers. Starwin is not only a name in the supply chain, but also an extension of the brand’s customers’ design and development capabilities.

Triple Value Proposition for B2B Partners:

✓ Precision Design Capability: 20-year pattern database × global trend analysis ensures commercially viable designs with aesthetic sophistication

✓ Agile Production System: From 50-piece sampling to 50,000-unit bulk orders, intelligent scheduling guarantees 98.6% on-time delivery

✓ Insight-Driven Strategy: Data-powered hit prediction engine builds product matrices (30% essentials/50% trend-led/20% functional)

We understand: a good lingerie from drawing to garment requires quality control across 137 processes, and more importantly, we need to understand the declaration of women under the cover of lace – sexy is the armor of self-identity, and tenderness is the texture of inner strength.

As the invisible partner of 30+ international brands, Starwin has always practiced the promise of “Manufacturing is Empowering”: when you give us your design, what you get is not only a reliable product that meets the SEDEX certification, but also a think tank with 19 years of industry genes.

Let every delivery

becomes an extension of the customer’s brand value

All of them will be transformed into the tenderness of women’s body.

Starwin, China’s high-end lingerie manufacturing solution

Started in 2005, focusing on the beginning

MAJOR DESIGNER

I am Laoluadeola. As a fashion designer, my work is a blend of creativity, technical skill, and hands-on practice.

From gathering initial inspiration, conducting in-depth market research, sketching designs, carefully selecting the right fabrics, to finally presenting the finished garment, each stage lays the foundation for creating unique and stylish clothing pieces.

Ensuring that the final product is showcased in its best form, it becomes a perfect fusion of creativity and quality.

Trustworthy Manufacturing Process

To ensure the highest product quality, we have multiple quality control checkpoints throughout the production process. From raw material selection to each stage of production, we implement strict quality controls to ensure that every product meets our customers' expectations. We are committed to delivering the best products to you, and that's why we place great emphasis on quality inspection at every step

This step involves evaluating the garment’s durability and performance under mechanical stress to ensure it meets industry standards for wear and tear.

The fabric is carefully inspected for any defects such as holes, snags, or inconsistencies in texture to maintain high-quality material standards.

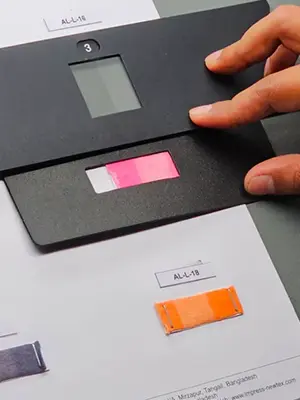

We ensure the color of the fabric matches the design specifications, ensuring consistency across all garments in the order.

This test checks the fabric’s ability to retain its color and quality after multiple washes, ensuring long-lasting performance.

The elasticity of garments, especially in lingerie and sportswear, is tested to guarantee comfort, durability, and the right level of stretch.

Throughout production, each step is monitored to ensure adherence to quality standards, minimizing errors or defects in the final product.

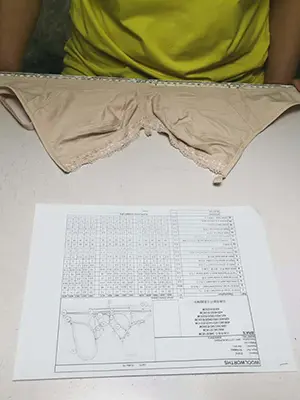

Garments are measured precisely to ensure they meet the size specifications, ensuring a perfect fit for the end-user.

Before package, each item undergoes a thorough final inspection to check for any defects, ensuring the highest quality before delivery.

Committed to Quality, Built for Your Success!